Ace Info About How To Build A Table Saw Extension

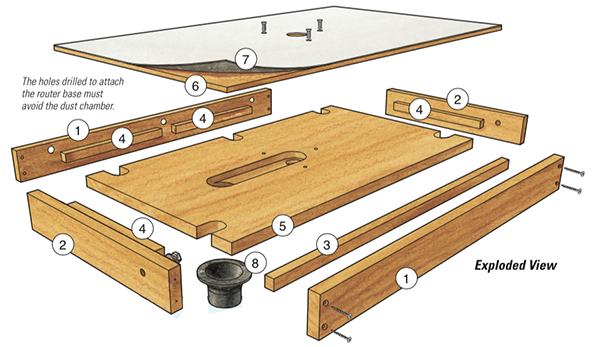

Fasten the pivoting leg braces to the leg's back panel, then glue and screw the beveled.

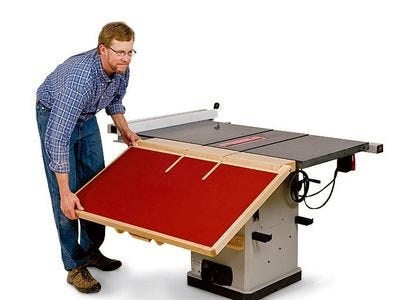

How to build a table saw extension. Attach the table extension to the saw with the 3/16 bolts, washers, and wing nuts. You can use brads to keep the pieces from shifting while clamping them. After completing the second extension, lift them up into position;

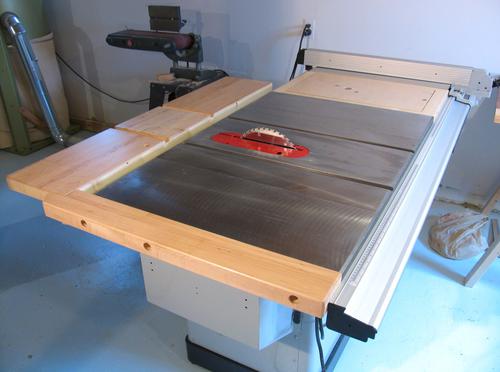

If you have an existing guide rail, the extension can be drilled through it. I cut out the square with a circular saw and built a very simple table based off those dimensions. Print yourself an adapter for the vacuum hose, of a shape much like an s.

This can be a cheap option if you have material available already in your shop. You surely know someone with a 3d printer, if you don't have one yourself. (make sure to keep the rest of the mdf, that will be used for the extension.

Then, drill and mark the. Next, you’ll want to position the outfeed. You can then connect the.

Then screw on the plywood back followed by the top. Purchase a table saw fence extension kit made specifically for your table saw make and model; To do this, you’ll first want to make sure that the outfeed table is the same height as the table saw.

Screw runners to the base after you attach the dividers. Then, glue them together and set them in place. So i hacked it into 1 1/2 lengths, filed it clean, and welded.

![How To Build A Homemade Table Saw Extension With A Router Table Built In. [Part 1] - Youtube](https://i.ytimg.com/vi/5PcvWmlyJTc/maxresdefault.jpg)